Power

Hindalco

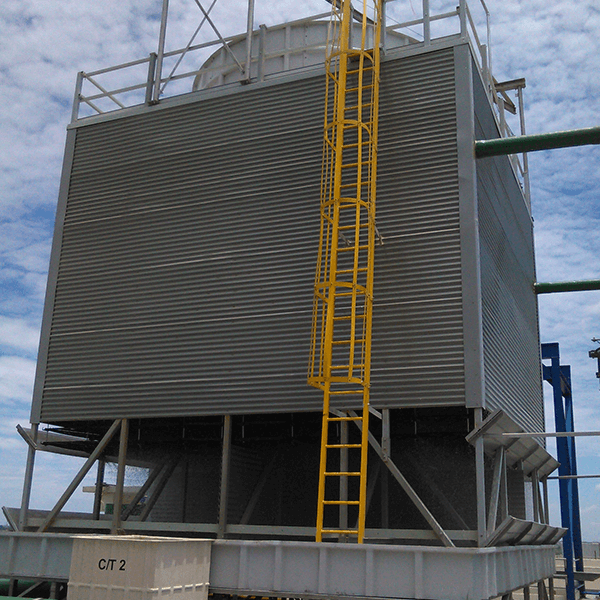

Fills replacement helps Hindalco achieve higher cooling tower performance

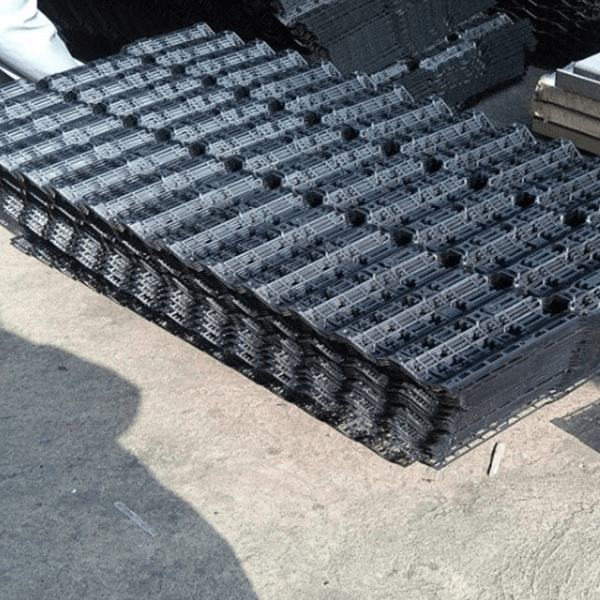

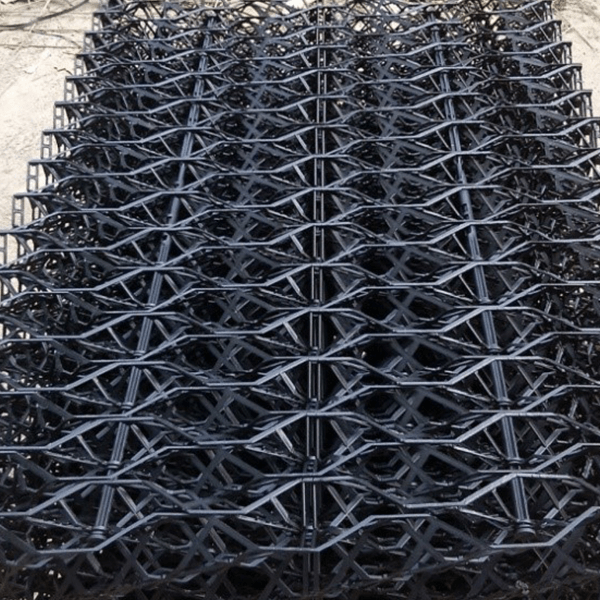

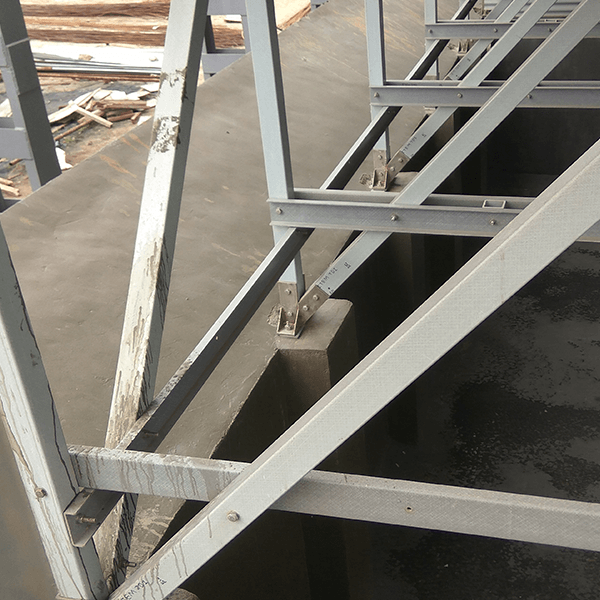

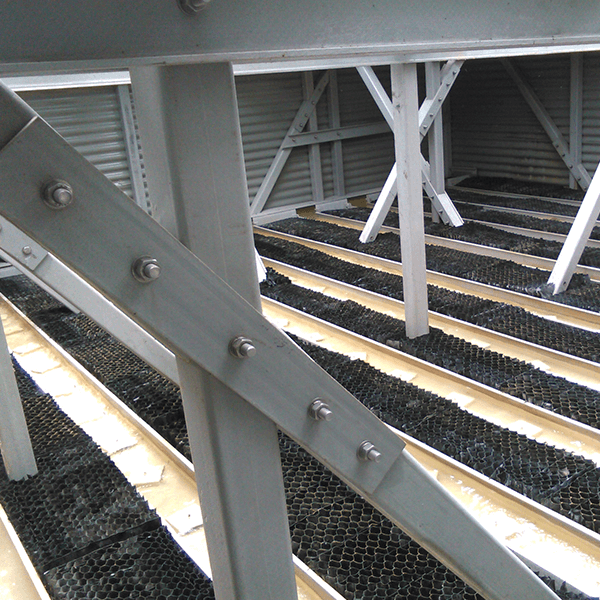

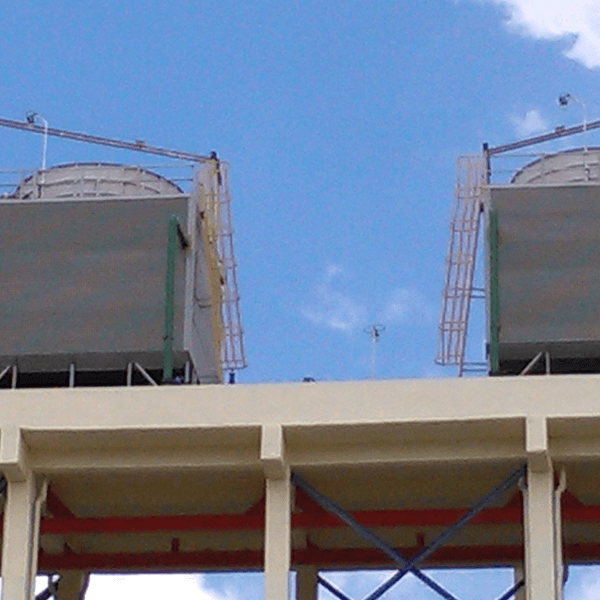

Hindalco was troubled with the poor performance of their existing cooling tower. After an extensive study, Encon suggested replacing the fills. Based on the water chemistry it was decided to change the fills to trickle fills.

The outcome of this change was cooling tower performance improvement by achieving 4.65°C in cold water temperature.