Encon Fans have a wide range of specifications and can be customized to suit your requirements.

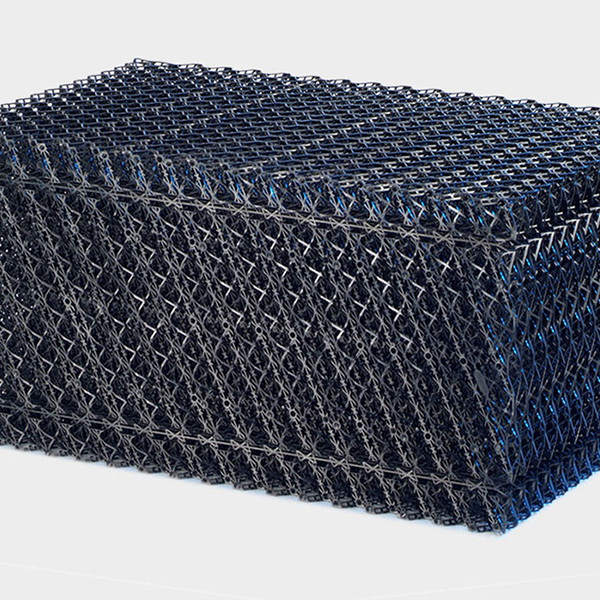

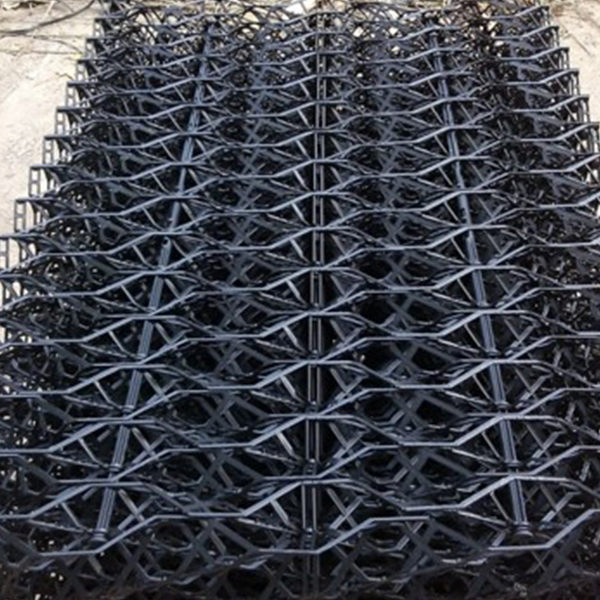

The use of Pultruded FRP in the fans of our Cooling Towers has additional advantages:

Encon fans have wide application range, spanning across various surroundings and industries.

– Mines & Ventilation

– Petrochemicals

– Power Plants

– Oil & Gas

– Textiles

– Cements

– Pulp & Papers

– Steel & Metals

– Foods

– Chemicals

– High Rise Buildings

– Hotels

– Hospitals

– Department Stores

– Cooling Tower

– Air Cooled Condensers

– Humidifier

– Air Washer

– Radiator Engines

– Dryers / Kiln Shell

– HVAC

– Man Cooler

For more information or to switch to Encon, write to us. Our team will reply within 24 hours.